Services

WHAT PRODUCTS WE HAVE

We offer a wide range of high-quality blister tray products, including custom-designed packaging solutions for pharmaceuticals, electronics, cosmetics, food items, medical devices and retail products, crafted to ensure maximum protection and aesthetic appeal

Features

Check Our Services

Blister Tray

A blister tray is a type of packaging commonly used to encase and protect items, particularly consumer goods, medical supplies, and electronic components. It typically consists of a pre-formed plastic cavity (or multiple cavities) that securely holds products, sealed with a backing material such as foil, paperboard, or plastic film.

Key Features of Blister Trays:

- Made from materials like PVC, PET, or RPET, which can be molded to fit the product shape.

- Transparent plastic is often used for product visibility.

- Customizable cavities to snugly hold individual items.

- Can be tailored to specific shapes for aesthetics and functionality.

- Sealed with a heat-sealing layer or pressure-sensitive adhesive.

- Tamper-evident seals can enhance product safety.

- Pharmaceuticals: To hold tablets, capsules, or medical devices.

- Consumer Electronics: For items like headphones or batteries.

- Retail Products: Toys, hardware, or beauty products.

- Protects against moisture, contamination, and physical damage.

- Lightweight and easy to transport.

- Provides clear product visibility for customers.

- Increasing use of recyclable or biodegradable materials to reduce environmental impact.

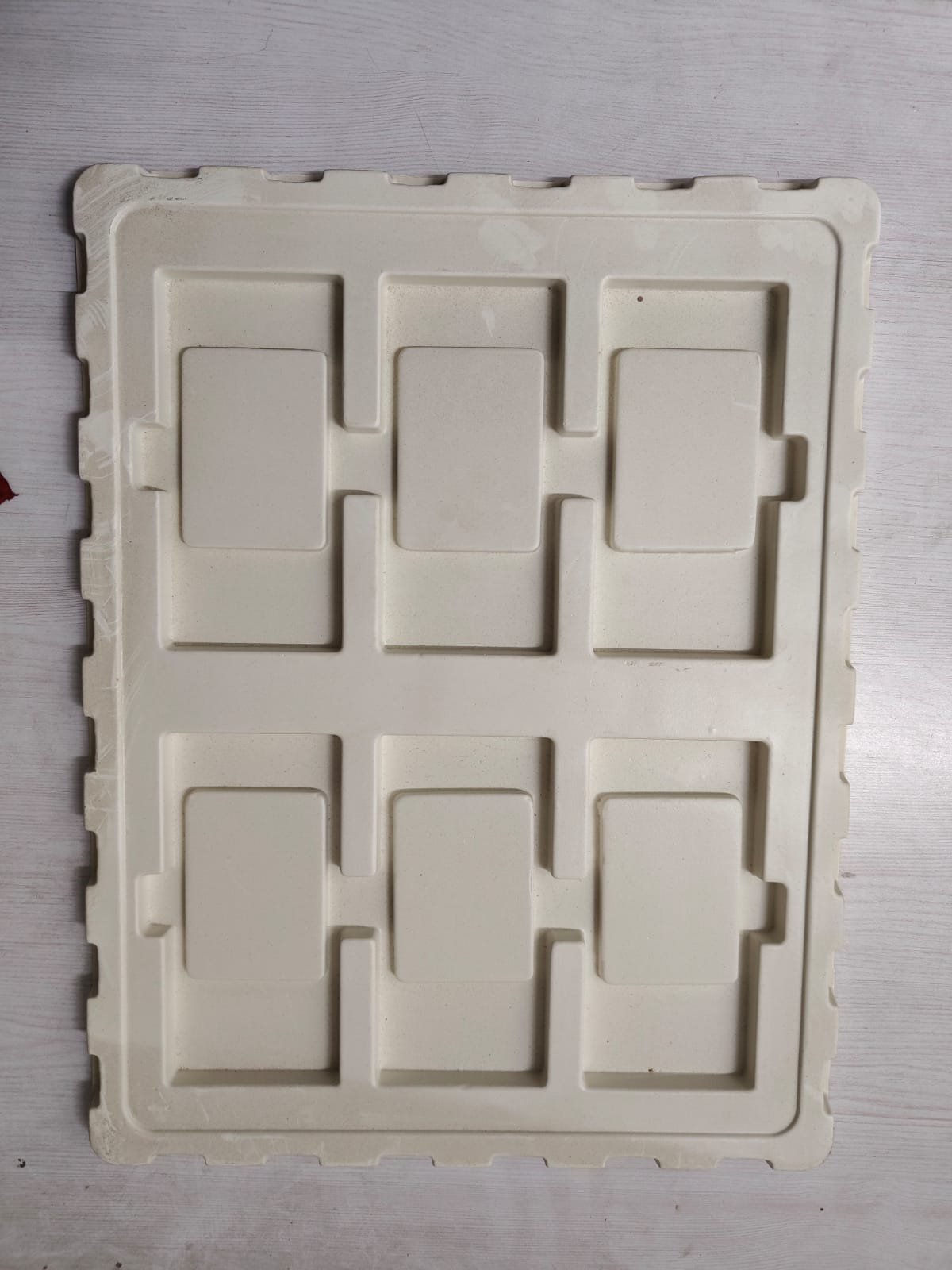

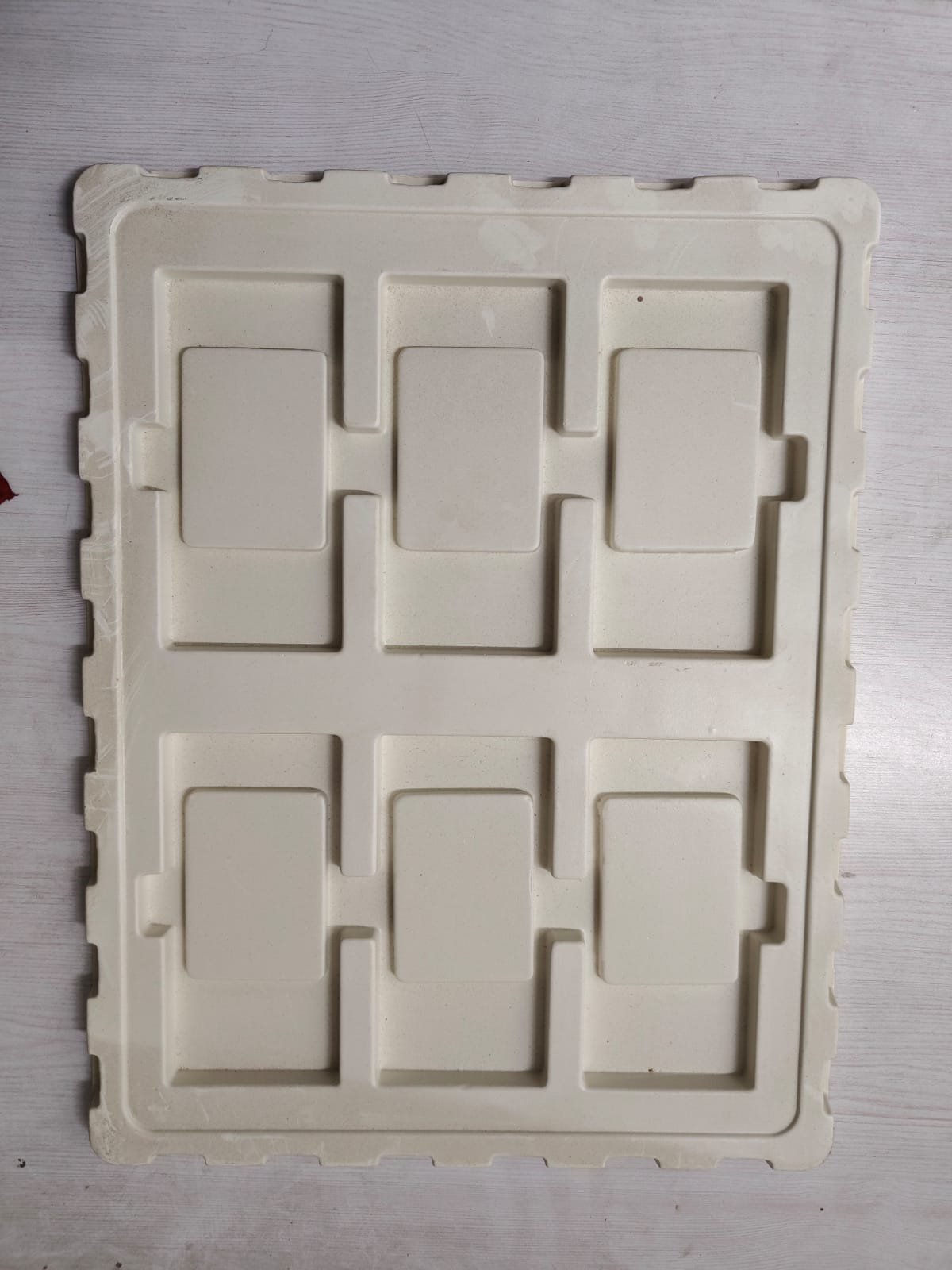

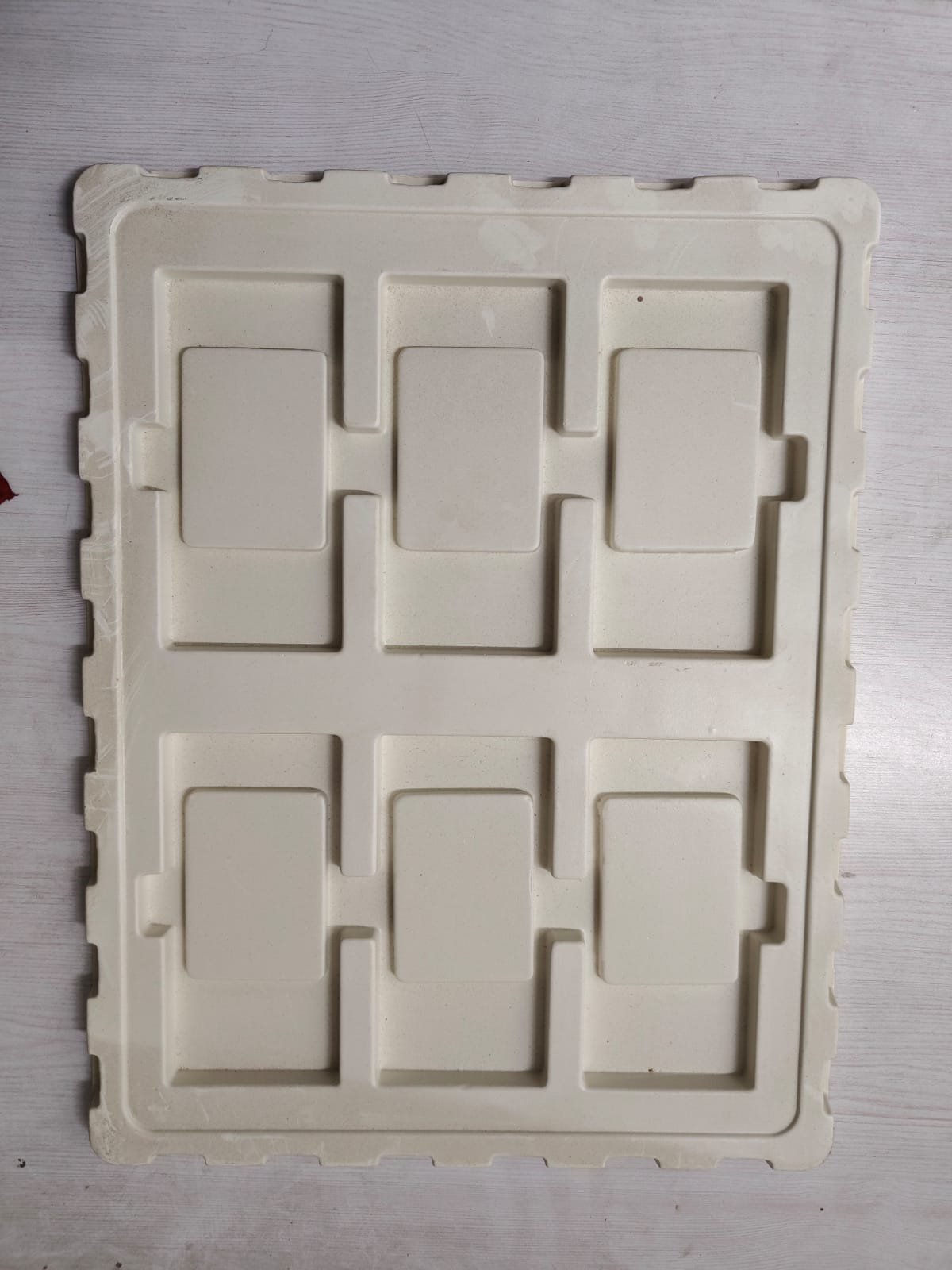

HIPS Blister Tray

A HIPS blister tray refers to a blister tray made from High Impact Polystyrene (HIPS), a durable and lightweight thermoplastic material widely used in packaging due to its excellent strength-to-weight ratio, ease of forming, and cost-effectiveness. HIPS blister trays are commonly utilized in various industries, including food, electronics, cosmetics, and medical supplies.

Key Features of HIPS Blister Trays:

- High Impact Resistance: HIPS can withstand significant force without cracking, making it ideal for protective packaging.

- Lightweight: Reduces shipping costs and overall material usage.

- Ease of Thermoforming: The material can be easily shaped into custom designs, making it suitable for precise product fits.

- Cost-Effective: Affordable compared to other plastic materials like PET or PVC.

- Can be molded into various shapes and sizes to securely hold items.

- Offers smooth surfaces for aesthetic appeal and ease of labeling.

- Food Packaging: Trays for baked goods, fruits, or ready-to-eat meals (though HIPS may need a food-grade coating for direct food contact).

- Medical Supplies: Holding instruments, syringes, or pharmaceuticals.

- Retail and Electronics: Housing small gadgets, batteries, or cosmetics.

- Compatible with heat-sealing or pressure-sensitive adhesives for tamper-evident closures.

- Can be paired with a clear plastic or foil cover for visibility and protection.

- Available in various colors and finishes (e.g., matte, glossy).

- Can be printed or embossed for branding and product information.

- HIPS is recyclable but not biodegradable.

- Increasing availability of recycled HIPS materials contributes to sustainability efforts.

Corrugation Box

A corrugation box (commonly known as a corrugated box) is a packaging solution made from corrugated fiberboard, which consists of three layers: an inner liner, an outer liner, and a fluted layer sandwiched between them. These boxes are widely used for shipping, storing, and protecting products across various industries due to their strength, durability, and versatility.

Key Features of Corrugation Boxes

- The fluted layer provides cushioning, making the box resistant to impact and suitable for handling fragile items.

- Easy to handle and transport without adding significant weight to shipments.

- Can be tailored in terms of size, thickness, printing, and design to meet specific packaging needs.

- Made from recyclable materials and often biodegradable, making them an environmentally responsible choice.

- Affordable for both small and large-scale packaging requirements.

Blister Tray PET

A Blister Tray PET refers to a type of packaging made from Polyethylene Terephthalate (PET) material designed to hold and protect products. These trays are commonly used in industries such as pharmaceuticals, electronics, food, and retail. PET is a popular choice because it is lightweight, durable, transparent, and recyclable.

Key Features of Blister Tray PET

- PET is known for its strength, clarity, and barrier properties, making it suitable for displaying products while protecting them from external elements.

- Customizable cavities to securely hold products.

- Often sealed with a backing card or a heat-sealed film.

- Can be thermoformed to fit specific product shapes.

- Pharmaceuticals: Blister packs for tablets and capsules.

- Electronics: Securely holding components or small devices.

- Retail: Displaying items like toys, tools, or accessories.

- Food: Packaging for items like baked goods or chocolates.

- Protection: Shields products from moisture, dust, and contamination.

- Transparency: Allows consumers to view the product without opening the packaging.

- Recyclability: PET is widely accepted for recycling, making it an eco-friendly option.

- Lightweight: Reduces shipping costs and material usage.

Blister Tray PVC

A Blister Tray PVC refers to packaging made from Polyvinyl Chloride (PVC), designed for holding and protecting products in various industries such as pharmaceuticals, electronics, and retail. PVC is a commonly used material due to its affordability, durability, and ease of thermoforming.

Key Features of Blister Tray PVC

- Durable: Resistant to physical impact, ensuring product safety.

- Transparent: Offers good visibility, allowing customers to view products without opening the packaging.

- Formability: Easily shaped to create custom cavities for specific products.

- Customizable shapes and sizes tailored to product requirements.

- Can include cavities, partitions, or additional design elements to hold multiple items securely.

- Pharmaceuticals: Packaging tablets, capsules, or medical devices.

- Retail Products: Toys, tools, batteries, and small hardware items.

- Electronics: Housing components like earphones or small parts.

- Food Industry: Some non-food-contact applications.

- Cost-Effective: PVC is more economical compared to other materials like PET.

- Protective: Shields products from moisture, dust, and physical damage.

- Versatile: Compatible with heat-sealing and other closure methods.

- Compatibility: Works well with various sealing films or backing cards.

- Recyclability: PVC is less eco-friendly than alternatives like PET, as it is harder to recycle and can release harmful chemicals during disposal.

- Chemical Sensitivity: Not suitable for all chemical or high-temperature environments.

- Clarity: PVC is slightly less transparent than PET.

- Cost: PVC is generally cheaper.

- Recyclability: PET is more sustainable and widely recycled.

- Strength: PET is stronger and more impact-resistant.

PET Sheet

A PET sheet is a plastic material made from Polyethylene Terephthalate (PET), widely known for its clarity, durability, and versatility. PET sheets are commonly used in packaging, thermoforming, and various industrial applications due to their excellent strength-to-weight ratio, recyclability, and food-safe properties.

Key Features of PET Sheet

- PET sheets offer excellent transparency, making them ideal for packaging where product visibility is essential.

- Resistant to impact, wear, and moisture, ensuring long-lasting performance.

- Easy to mold into complex shapes, making it suitable for custom packaging solutions.

- Non-toxic and FDA-approved for direct food contact.

- Environmentally friendly and widely accepted in recycling programs.

Packaging Items

Packaging items refer to materials and components used to wrap, protect, store, and present products. Packaging serves multiple purposes, including protection during transportation, branding, and providing essential product information.

\

\